Automotive Components

The manufacturing of automotive components is a critical segment of the automotive industry, encompassing a wide range of parts, systems, and technologies that are essential for building vehicles. This process involves transforming raw materials into finished components that meet strict standards of quality, safety, and performance. Here’s an overview of the key aspects of automotive component manufacturing:

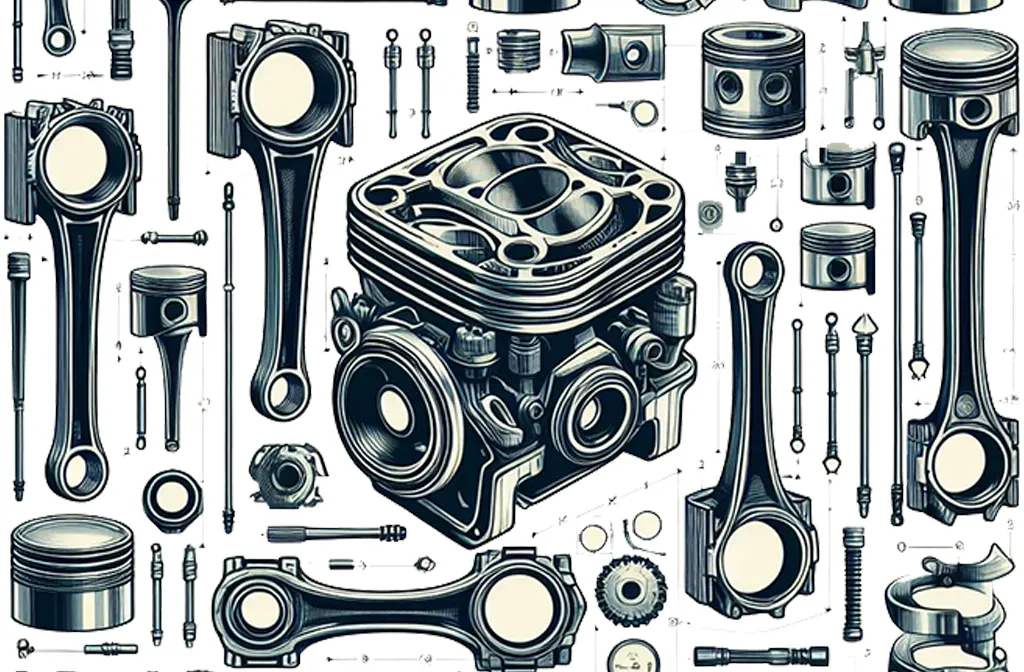

Engine and Powertrain Components: These include engine blocks, pistons, crankshafts, camshafts, and transmission parts. They are the heart of the vehicle, responsible for generating and transmitting power.

Chassis and Suspension Parts: This category includes frames, axles, shock absorbers, and control arms, which provide structural support and stability to the vehicle.

Electrical and Electronic Components: These are increasingly significant, especially with the rise of electric vehicles (EVs). They include batteries, electric motors, sensors, and control modules.

Interior Components: Seats, dashboards, and infotainment systems fall under this category, focusing on comfort, aesthetics, and user interface.

Exterior Parts: These include body panels, bumpers, and lighting systems, which contribute to the vehicle’s aerodynamics and aesthetics.

We’ve

Years

Experience

Quality Control and Standards

Techniques like X-rays and ultrasonic testing ensure that components have no internal defects.

Precision measuring tools and CMM (Coordinate Measuring Machines) verify the dimensions and tolerances of parts.

Components undergo rigorous testing under simulated conditions to ensure they perform as expected.